Flash Battery has launched its new laser-welding automated module meeting line.

The results of an funding of over €6 million, the brand new line is the core of the corporate’s current headquarters growth which added 2,200 sq. metres devoted to a completely automated space for battery module meeting.

With an annual manufacturing capability reaching 90,000 modules, this division is designed to deal with all the welding and mechanical integration course of inside a managed surroundings.

Flash Battery has chosen to internalize and develop all key course of abilities inside its HQ: from its proprietary battery administration system to mechanical and electrical design, course of validation, and predictive upkeep.

With the mixing of this new module meeting line, the corporate finalizes its in-house manufacturing consolidation course of, now additionally instantly controlling welding and meeting actions beforehand outsourced to exterior suppliers. Apart from the cells – sourced from prime international producers – each part is now managed and supervised instantly by Flash Battery.

This built-in administration mannequin permits the corporate to ship absolutely tailor-made options aligned with every buyer’s software wants, sustaining constant requirements of high quality and efficiency, even in advanced and dynamic industries.

“Bringing battery module meeting in-house means going on to the supply of the availability chain,” says Marco Righi, CEO and founding father of Flash Battery. “For cells, we depend on main international suppliers, deciding on a number of suppliers for every sort to extend provide chain reliability and improve our negotiating energy. Latest geopolitical and financial developments have confirmed the significance of getting direct management over manufacturing to scale back lead instances and provide points.”

The brand new meeting line is engineered to rapidly change between configurations, managing 13 module variants with changeover instances of lower than 10 minutes. This permits Flash Battery to reply rapidly and precisely to even probably the most particular buyer necessities, supporting the creation of optimized electrical techniques with out compromising on time or high quality.

Laser welding ensures stronger mechanical and electrical joints, larger resistance to vibrations and decrease power dispersion. That is important for reaching secure and dependable efficiency, significantly in demanding industrial functions.

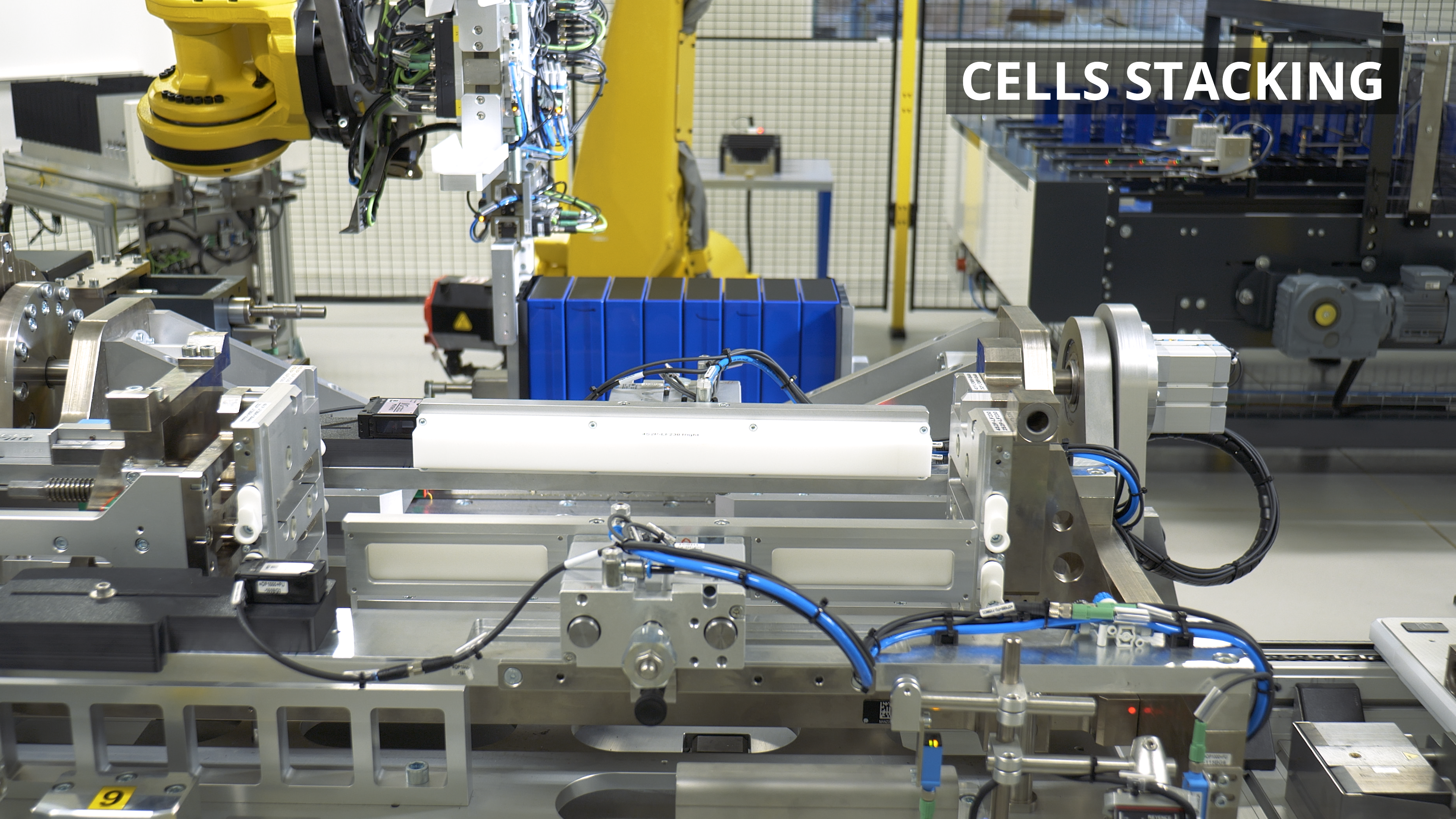

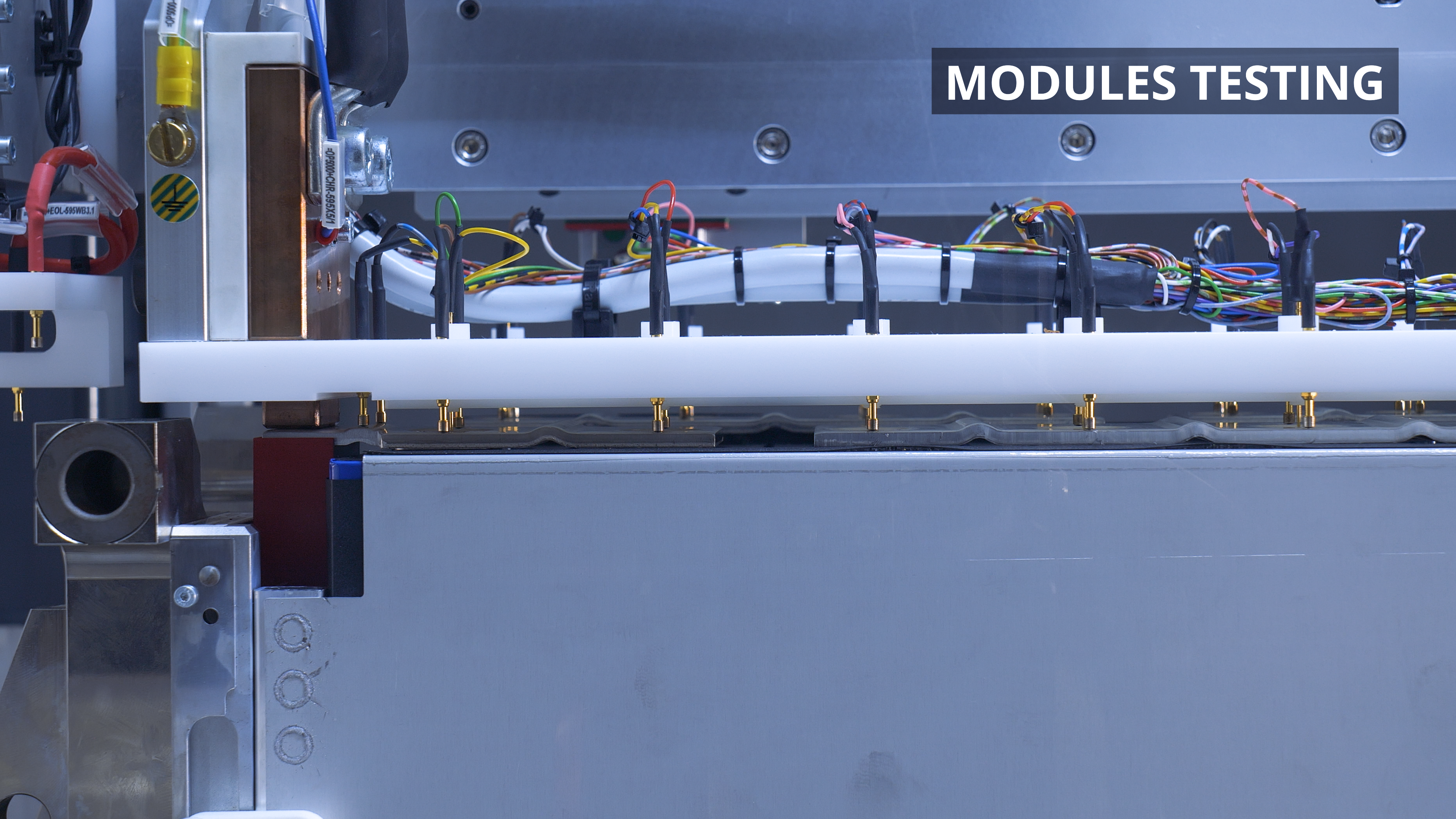

The road operates by 4 core automated phases. The primary is cell loading and automatic inspection utilizing optical inspection techniques and high-precision sensors. Subsequent is module formation with robotic stacking and placement of parts right into a containment construction for subsequent welding. Then, laser welding of frames and bus bars join the cells for a sturdy and environment friendly electrical connection. Closing compliance testing embody security, insulation, and mechanical resistance checks. Solely modules that cross all checks are labelled and despatched to Flash Battery’s battery pack meeting traces.

“With this new line, we’re taking a decisive step towards a extra autonomous, environment friendly, and dependable manufacturing mannequin,” provides Marco Righi. “Integrating manufacturing abilities permits us to reply promptly to buyer wants and ship tailor-made options with top-tier high quality and efficiency. This can be a key aggressive benefit in a continually evolving market.”

With this sturdy in-house autonomy, and the upcoming launch of European gigafactories devoted to LFP (Lithium Iron Phosphate) cell – a secure, secure, and cobalt-free lithium expertise – Flash Battery will quickly be capable to provide clients a completely European provide chain.

Pictures courtesy of Flash Battery