How can OEMs efficiently navigate the vitality transition throughout various off-highway functions? Engine producers present versatile multi-energy methods spanning HVO compatibility, hydrogen combustion and modular platforms to speed up various gasoline adoption

Off-highway OEMs face mounting stress to decarbonise their machine portfolios whereas sustaining the efficiency and reliability their buyer’s demand. With Stage VI emissions laws on the horizon and sustainability commitments deepening, OEMs are actually searching for powertrain options that may carry out throughout a spread of functions.

This problem extends past merely swapping engines. OEMs should navigate infrastructure limitations, gasoline availability and the complicated responsibility cycles that outline off-highway operations. A mix harvester working in distant farmland faces totally totally different constraints to an excavator engaged on a building web site, but each require energy options that meet more and more stringent environmental requirements.

Engine producers FPT Industrial, AGCO Energy and Cummins are responding with multi-energy methods designed to provide OEMs most flexibility. Every provider is taking totally different however comparable approaches to decreasing carbon emissions, providing options equivalent to drop-in HVO compatibility, or modular platforms that may change between hydrogen and diesel with minimal machine redesign.

Constructing a multi-energy momentum

“Our product line follows a multi-energy strategy to seek out the right combination of options designed to cut back international emissions and drive the vitality transition in direction of a cleaner future, all the time alongside our prospects,” says Andrea Gerini, head of open innovation at FPT Industrial. “On the one hand, we proceed to develop new inner combustion engines, utilizing more and more sustainable fuels equivalent to biomethane, hythane, hydrogen and HVO. However, we feature on our analysis and manufacturing of latest electrified zero-emission options, suitable with each on- and off-road functions.”

“The vitality transition isn’t in query anymore. The query is tips on how to help this transition with options that may be accepted economically”

This diversified technique displays the complicated actuality of off-highway operations. Not like on-road functions, industrial autos face excessive variations in responsibility cycles, working environments, and infrastructure availability. A single resolution can’t deal with the breadth of functions from building websites to distant agricultural operations. AGCO Energy’s strategy exemplifies this pondering. “The way in which we strategy the altering market boils all the way down to our slogan: Wider Spectrum of Energy. It describes the necessity for various options to fulfill the person wants of various buyer teams and places,” says AGCO Energy product specialist Tapani Katila.

AGCO’s Core engine platform demonstrates this philosophy in observe. “Functions underneath 100 horsepower are best suited for electrification. With present battery know-how weight and space-claim restrict the implementation of battery-electric options in heavier functions. We consider functions requiring over 100 horsepower will seemingly be powered by hybrid options or combustion engines operating on various fuels, like our Core engine,” says Katila.

HVO leads various gasoline adoption

Among the many out there various fuels, hydrotreated vegetable oil (HVO) has emerged as essentially the most readily adoptable resolution for current fleets. Each FPT Industrial and AGCO Energy have made all their engines HVO-compatible, providing quick decarbonisation advantages with out requiring infrastructure modifications. “HVO is a really attention-grabbing candidate to help the defossilisation pathway of diesel engines. The ultimate product is absolutely suitable with present engine applied sciences, making it a drop-in resolution. In comparison with biodiesel (e.g. FAME), HVO can be utilized in no matter mix with typical diesel and in addition as neat product,” says Gerini. “Resulting from its chemical composition, it brings glorious properties for a clear and environment friendly combustion, however the true profit comes when contemplating the CO2 efficiency underneath a well-to-wheel perspective. HVO brings a CO2 emissions discount of as much as 85% in comparison with typical diesel measured at well-to-wheel (WtW) stage, demonstrating that the decarbonisation course of can be leveraged on typical engine applied sciences, simply through the use of the proper vitality service.”

AGCO Energy’s decade-long expertise with HVO has additionally demonstrated sensible benefits. “In comparison with typical diesel, HVO has the next cetane quantity which implies that it combusts extra simply – for instance in colder climates,” says Katila. “ This implies it burns extra purely and produces much less soot, and extra importantly leads to decrease particle emissions. From a sensible viewpoint, HVO has a for much longer shelf life in comparison with typical diesel.”

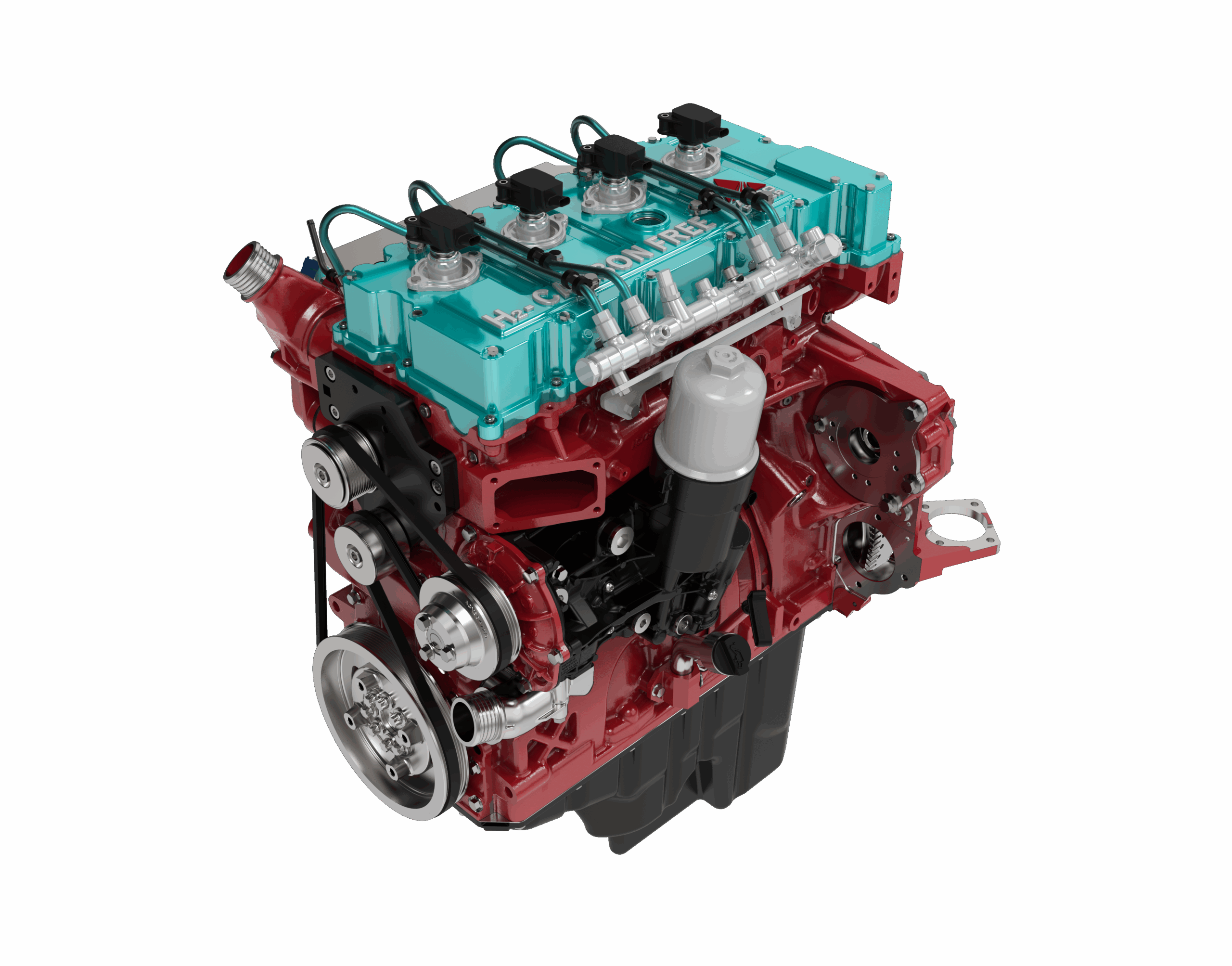

Hydrogen combustion for demanding functions

Whereas HVO addresses quick wants, hydrogen combustion engines are being developed for essentially the most difficult off-highway functions. FPT Industrial’s displacing tonnes of snow on excessive ski slopes, generally at very excessive altitude underneath extreme climate circumstances. Testing circumstances are fairly extreme, and particular options have been conceived to make sure the machine gradeability and the cold-start circumstances. We used our experience in gaseous engines to develop the primary hydrogen model of our 13-litre engine, concentrating on diesel equal efficiency on the highest effectivity, to help the laborious mission of those machines.”

Gas flexibility

A key pattern rising throughout producers is the event of modular engine architectures that may accommodate a number of gasoline varieties with out requiring full redesigns.

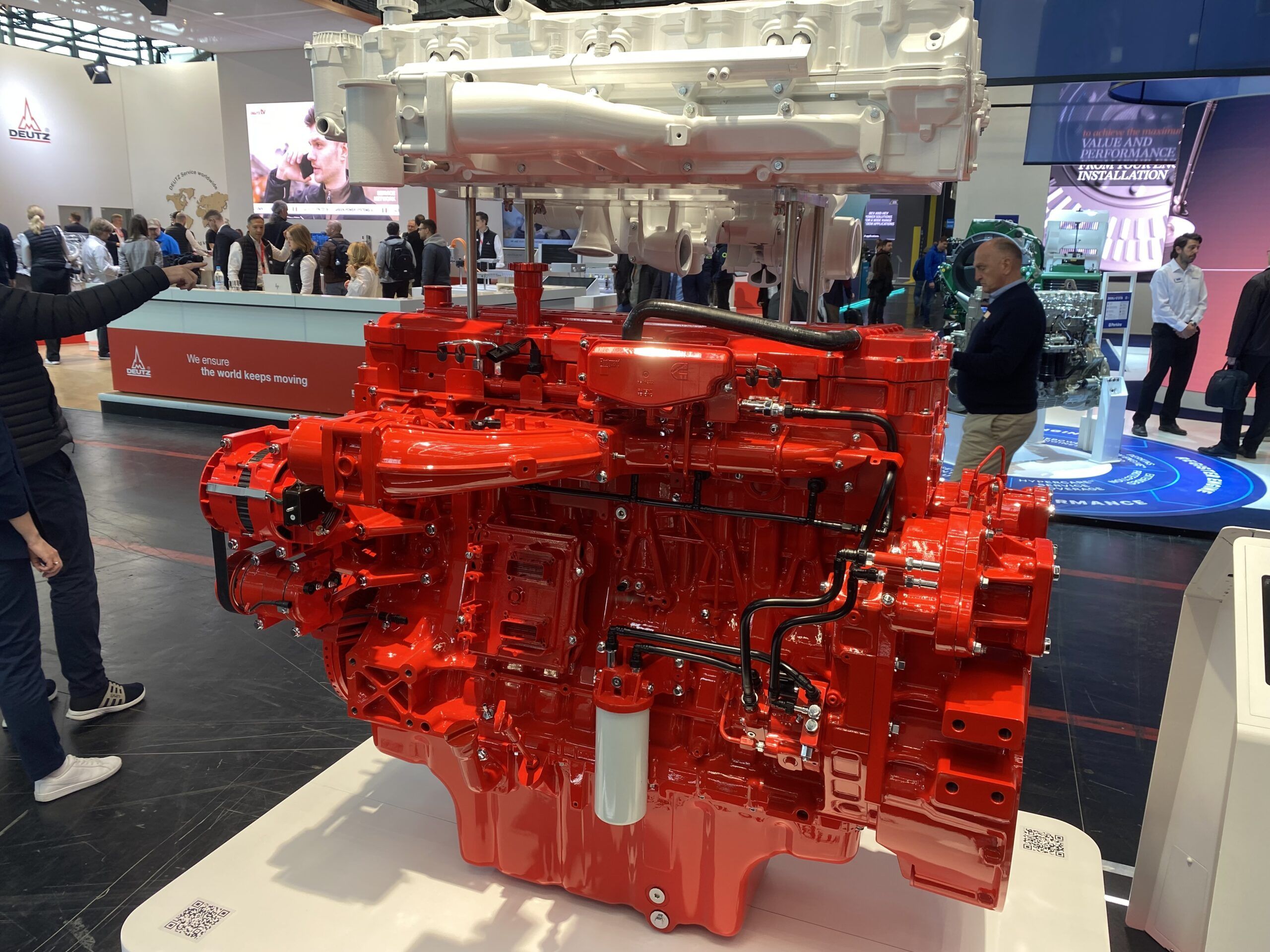

In April, at Bauma in Munich, Cummins showcased this strategy with its next-generation X15 engine, a 15-litre engine with interchangeable heads for hydrogen and diesel operation. “The cool factor about that is that our OEMs can decide if they need hydrogen or diesel for his or her future construct merchandise, and so they don’t should massively reconfigure the gear to accommodate that,” Sarah Myers of Cummins informed iVT on the occasion. “Strolling round Bauma, you see all this various gear that usually requires redesigns for various gasoline varieties. To have the ability to provide one thing like this to OEMs the place they’ll have the proper resolution, irrespective of the place they’re working, is de facto invaluable.”

AGCO Energy’s Core platform additionally goals to accommodate totally different gasoline varieties throughout the similar envelope. “The inspiration of Core engines lies within the placement of the camshaft within the cylinder head,” says Katila. “This design alternative provides better flexibility in configuring and positioning valve prepare elements. For instance, it permits for the event of distinct designs for gaseous and liquid fuels while not having to think about the constraints of push rod placement.”

Diesel-electric hybridisation has been considered up to now as an answer to the restrictions of battery energy in bigger machines. Nevertheless, burning diesel even in small quantities is wanting removed from future proof. AGCO Energy’s eHydrogen prototype supplies a zero-emission hybrid various by combining electrical programs with hydrogen combustion. “This prototype was developed to reply the rising demand for decreasing CO2 emissions and to showcase the capabilities of the Core engine platform,” says Katila. “It combines the perfect of combustion and electrification – quick response and low NOx emissions because of the hybrid system, and reliability and cost-efficiency of the combustion engine platform. The truth is, the prototype makes use of 80% of the identical elements because the diesel serial manufacturing model of the engine.”

“The inspiration of core engines lies within the placement of the camshaft within the cylinder head. This design alternative provides better flexibility in configuring and place valve prepare elements”

Infrastructure challenges

Regardless of the key technological advances, infrastructure limitations proceed to constrain various gasoline adoption, notably for hydrogen functions. “We’re assured within the potential of our hydrogen combustion engine, however a number of market-related challenges nonetheless have to be addressed,” says Katila. “Whereas hydrogen exhibits nice promise as a gasoline, essentially the most vital hurdle is the dearth of infrastructure – particularly in distant areas. For hydrogen to turn out to be a viable choice, the manufacturing capability of inexperienced hydrogen from sustainable sources should enhance considerably. One other key issue is price; hydrogen should turn out to be aggressive with current options equivalent to electrical energy and liquid fuels.”

Nevertheless, progressive options are rising, and AGCO Energy sees alternatives of their experience with energy era. “At Agritechnica in 2023 we shared our imaginative and prescient for a microgrid idea, which might enhance the vitality independence in distant places, higher enabling the charging of electrical gear,” says Katila.

Adoption drivers and limitations

The receptivity of OEMs to various gasoline applied sciences varies based mostly on financial elements. “All sectors are requested to contribute to a defossilisation pathway, the vitality transition isn’t in query anymore,” says Gerini. “The query is tips on how to help this transition with options that may be accepted economically, contemplating each the price of the machine but additionally from an operational price standpoint.”

Katila agrees, highlighting the significance of price issues for OEMs. “On the finish of the day our prospects run companies, and their operations have to be sustainable not solely environmentally but additionally financially,” he says. “Price remains to be a problem with various fuels and energy options, which limits their adoption fee. A serious driver up to now has been laws, so we want to look to governmental actors for extra help, however infrastructure necessities and plain previous habits additionally have to be considered.”

Regional variations

Katila predicts the trail to various gasoline adoption will fluctuate by area, pushed by native sources and regulation. “In some areas, uptake may very well be notably robust. As an illustration, South America the place totally different biofuels present promise,” he says. “Nevertheless, on a world scale, progress could also be constrained by inhabitants pressures. Because the demand for meals will increase, arable land is extra prone to be allotted for meals manufacturing fairly than cultivating crops for sustainable gasoline.”

FPT Industrial’s international perspective reveals further regional alternatives. “Our pure approach to suppose multi-energy can also be the outcome from the worldwide footprint of our firm. Some options like HVO, bioCNG/LNG, hydrogen might have a world market, however there are additionally different attention-grabbing choices in some areas like bioethanol in Brazil,” says Gerini.

Powering the longer term

Within the short- to medium-term producers are getting ready for a various vitality panorama sooner or later fairly than convergence on a single resolution. “Contemplating the variety in functions within the offhighway sector, we have to have an entire panel of options leveraging high-efficient conversion, flexibility in use, reliability and capability to simply adapt to native availability of gasoline. We will think about a progressive change from typical fuels to biogenic fuels, then to artificial fuels, together with e-fuels, as soon as sustainable hydrogen and CO2 turn out to be out there at industrial scale,” says Gerini.

AGCO has set concrete targets to drive this transformation. “In help of our sustainability commitments and in response to evolving market wants,” says Katila. “AGCO has set a aim to introduce greater than 10 battery-electric and/or various gasoline succesful merchandise by 2033. This bold goal highlights our dedication to accelerating the adoption of fresh vitality options inside our portfolio. We’re dedicated to bettering powertrain effectivity by not less than 5% on new merchandise by 2033.

Because the off-highway business navigates this multi-energy future, success will rely upon producers’ capability to supply versatile, cost-effective options that meet various utility wants. The transformation is underway, pushed by regulatory necessities, sustainability commitments, and more and more superior applied sciences that make various fuels a viable actuality for the off-highway sector.

This text first appeared within the October challenge of iVT