Within the race to speed up automobile electrification, daring concepts are solely the start. For any idea to evolve right into a viable product, it should survive rigorous testing, validation, and iteration. On the centre of this transformation lies a vital however generally underestimated part: the integrity of the info that underpins each engineering resolution

In immediately’s electrical and hybrid automobile sector, growth timelines are tightening whereas the complexity of programs will increase. The strain to ship new battery, powertrain, and charging improvements is rising, however many engineering groups nonetheless deal with the early proof-of-concept (PoC) section as a low-risk stage, an area for exploration with out the complete weight of operational scrutiny. That mindset is turning into a legal responsibility. With out actual, full, and high-quality knowledge, even essentially the most promising ideas danger being delayed, misjudged, or discarded prematurely.

This problem got here into sharp focus throughout a collaboration between automobile knowledge options specialist Odosolutions and TAE Energy Options, a division of TAE Applied sciences.

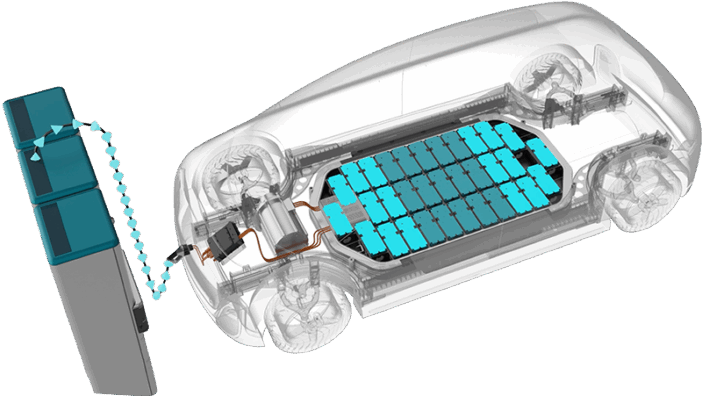

TAE Applied sciences is finest recognized for its pioneering work in fusion power; its TAE Energy Options division focuses on battery innovation – particularly, growing pulse charging programs designed to considerably enhance the way in which lithium-ion batteries are charged. Their purpose: to allow quicker, safer, and extra environment friendly charging cycles throughout numerous battery chemistries. However reaching that concentrate on required greater than imaginative and prescient. It required data-rich validation beneath real-world circumstances.

To show the viability of its pulse charging idea, TAE wanted to simulate genuine use circumstances across the clock, throughout a number of battery configurations. Their PoC setting needed to run repeatedly, present real-time operational insights, and be certain that no anomaly or knowledge level was ever misplaced – even throughout surprising interruptions similar to community outages.

The corporate’s engineering groups, distributed throughout Europe and the UK, additionally wanted distant entry to work together with the system dwell, intervene when wanted, and collaborate throughout places immediately.

Actual-time outcomes

Odosolutions applied a distant knowledge infrastructure designed particularly for high-resilience, engineering-grade environments. The system enabled totally autonomous check rig operation, backed by real-time dashboards, safe onboard and distant knowledge logging, and immediate alert mechanisms. Engineers might monitor progress, alter parameters, and obtain alerts about anomalies from anyplace, with out the have to be bodily current on the facility.

This shift in functionality didn’t simply add comfort – it altered the tempo and confidence of growth. The system’s onboard logging ensured that every one knowledge captured throughout community dropouts was robotically synchronised as soon as connectivity was restored. With a whole knowledge path and distant entry in place, the TAE staff was capable of detect and act on points in actual time, moderately than after the actual fact.

Maybe extra importantly, the system offered a single supply of fact for each technical and non-technical stakeholders. Take a look at efficiency, security thresholds, and system behaviour might all be visualised in a central dashboard, permitting engineering leads, analysts, and decision-makers to work from the identical dwell knowledge. This not solely improved inside alignment but additionally supported clearer reporting and quicker decision-making.

The expertise underscores a broader precept more and more recognised throughout the electrical and hybrid automobile sector: the PoC section is just not merely a stepping stone – it’s the basis for every part that follows. At this stage, engineering groups are making vital judgments about efficiency limits, system security, cost-effectiveness, and scalability. Every of those selections relies on knowledge that’s full, correct, and instantly actionable.

But in lots of R&D environments, PoC tasks nonetheless depend on standalone logging instruments, handbook oversight, and after-the-fact evaluation. When anomalies go undetected or key thresholds are missed, the end result might be weeks of misplaced growth, misdiagnosed faults, or failed validation efforts. Worse nonetheless, this will introduce uncertainty for stakeholders who should approve the following section of growth or funding.

Accelerated growth

In distinction, correctly instrumented PoC environments present a robust platform for innovation. They permit quicker iteration, as engineers can trial, analyse, and refine programs shortly. They help design optimisation by reflecting precise working circumstances moderately than assumptions. And so they set up a scalable knowledge basis that may develop with the product, decreasing the necessity for rework or expensive retrofitting later.

The TAE undertaking illustrates these advantages clearly. With a real-time view of efficiency, immediate alerting, and uninterrupted knowledge continuity, the engineering staff was capable of speed up growth timelines whereas bettering general confidence within the outcomes. Security protocols had been additionally strengthened, as potential faults might be flagged and addressed earlier than inflicting harm. And with distant entry enabled, geographically dispersed groups had been capable of collaborate extra successfully, minimising the logistical burdens that usually decelerate superior testing programmes.

Because the push towards electrification intensifies, and as battery and charging applied sciences grow to be extra complicated, the strain on engineering groups to maneuver shortly with out compromising high quality will solely develop. On this context, knowledge isn’t just an operational software – it’s a strategic enabler.

Future applied sciences will succeed not solely by proving feasibility on the PoC stage, however by demonstrating efficiency with readability, credibility, and real-world proof. Excessive-fidelity knowledge platforms play a central function in that demonstration, enabling clear validation and strong decision-making at each stage of growth.

Finally, what separates a profitable innovation from an costly detour is usually not the thought itself, however the proof behind it. And within the quickly evolving world of electrical and hybrid automobile expertise, that proof should be strong, dependable, and able to drive vital selections from day one.